What Are Veneer Presses?

Most people have heard of veneer presses, the thin layers of wood normally less than 3 millimetres moulded and pressed into which ever shape is required. It has become a statement of cheap and cheerful furniture, but in the past it was far from that.

History of Veneer

The word veneer originated from a German word ‘Furnier’ which was taken from the French word ‘Fourier’, meaning to ‘supply or provide’. However, the veneering process was actually first recorded in ancient Egypt 1500 BC.

The Egyptians, living in desert and sandy areas, treated certain woods as if they were very precious. In some places, good wood was such a rarity that its price was equal to that of gems or jewels. They would take the wood and cut it into very thin pieces so they could get the most out of each supply.

Within the 19th century veneering was branded with a bad name. It developed the reputation of being a way of manufacturers using veneer mainly to cover over badly kept pieces of wood and therefore resulting in badly constructed pieces of furniture. It was seen as a way to save costs and get furniture created as quickly as possible.

Nowadays, veneer is a huge part of the furniture industry. No longer does it mean cheap or overly manufactured, it means getting the most out of each good piece of wood. Today, veneer products are very much in demand and are created using veneer presses.

So What Are Veneer Presses?

Veneer Presses are simply mechanical or hydraulic presses that focus on moulding or pressing a thin piece of good quality wood together with a piece that is of a lesser quality. The process of pressing the veneer is very straightforward and can create a number of different things.

Veneer is positioned on a substrate coated with adhesive, and then a caul (a piece of wood that is flat and used to distribute the weight) is placed on top. Once the three are clamped together using hydraulic or mechanic clamps, the pressure is applied.

Once the pressure has been applied which in some cases means using temperatures as well of up to 120 degrees, the veneer is ready to be molded into a variety of different shapes. The veneer can even be covered with a laminate material (lamination) so that it does not feel like wood, splinters less and can be used safely for a variety of household furniture.

What Are They Used For?

With all this talk of veneer presses are there even any uses for them? Of course, there are!

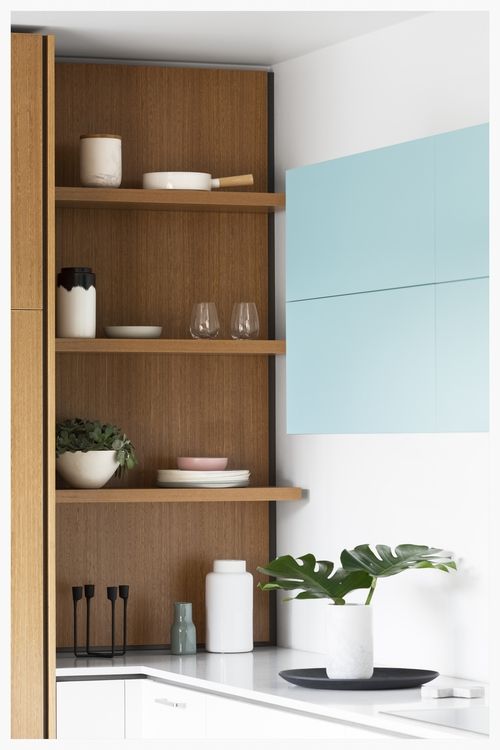

The most common use of a veneer press is for the door, kitchen or floor panels. These are perfect for giving the effect of high-end quality wood and being great value for money. Using a veneer press you can transform a great piece of wood into whichever shape or thickness you like.

Another great role of veneer is for making chairs and other pieces of furniture for your home. The range of products is huge and they are adaptable to any environment whether that be homes, schools, offices and many others.